dV/dt – What Is It and Why Should You Care?

Problems Caused From VFD Use:

Variable frequency drives (VFDs) are helpful in many applications. They can help to control speed and save energy, but they can also present problems. One of the side effects that you need to potentially mitigate is called dV/dt. Below we will describe what it is, why you should care, and how to fix it.

What is dV/dt?

VFDs create voltage spikes that go through the leads to the motor. The name comes from the equation that helps to describe the phenomenon, delta (Δ) Voltage / delta (Δ) time, with delta meaning “change.” In simpler terms, dV/dt is how the voltage spikes distort and amplify over the length of the leads. This is why you need to worry more about dV/dt the longer your lead lengths get from VFD to motor.

Manufacturers have different recommendations on how long a lead length can get before you need to start worrying about dV/dt. As a rule of thumb for low voltage drive applications, we tend to say that any lead length above 100 feet is where you should start to think about dV/dt issues. Most lead lengths above 500 feet are where we don’t feel comfortable quoting a drive without some sort of dV/dt mitigation strategy.

Why Should I Care?

Unlike harmonic issues, utilities typically don’t worry about dV/dt because the effects are all on the load side of the VFD. If utilities don’t care, why should you? In short, because dV/dt can destroy your motor’s windings. If you have long leads from your inverter to your motor, it can be both easier and cheaper to add a dV/dt mitigation device rather than to continually replace your motors.

A similar issue to factor in is the cost of replacing the motor. We find many applications where the cost of downtime is high enough that removing the risk of dV/dt-related failures is an easy financial decision. Quite often, the motor in the system is custom and would not be easy or cheap to repair or source a replacement for. We also see some applications, like motors down deep wells, where the cost of physically replacing the motors makes protecting that motor from dV/dt an obvious choice.

How Do I Fix dV/dt?

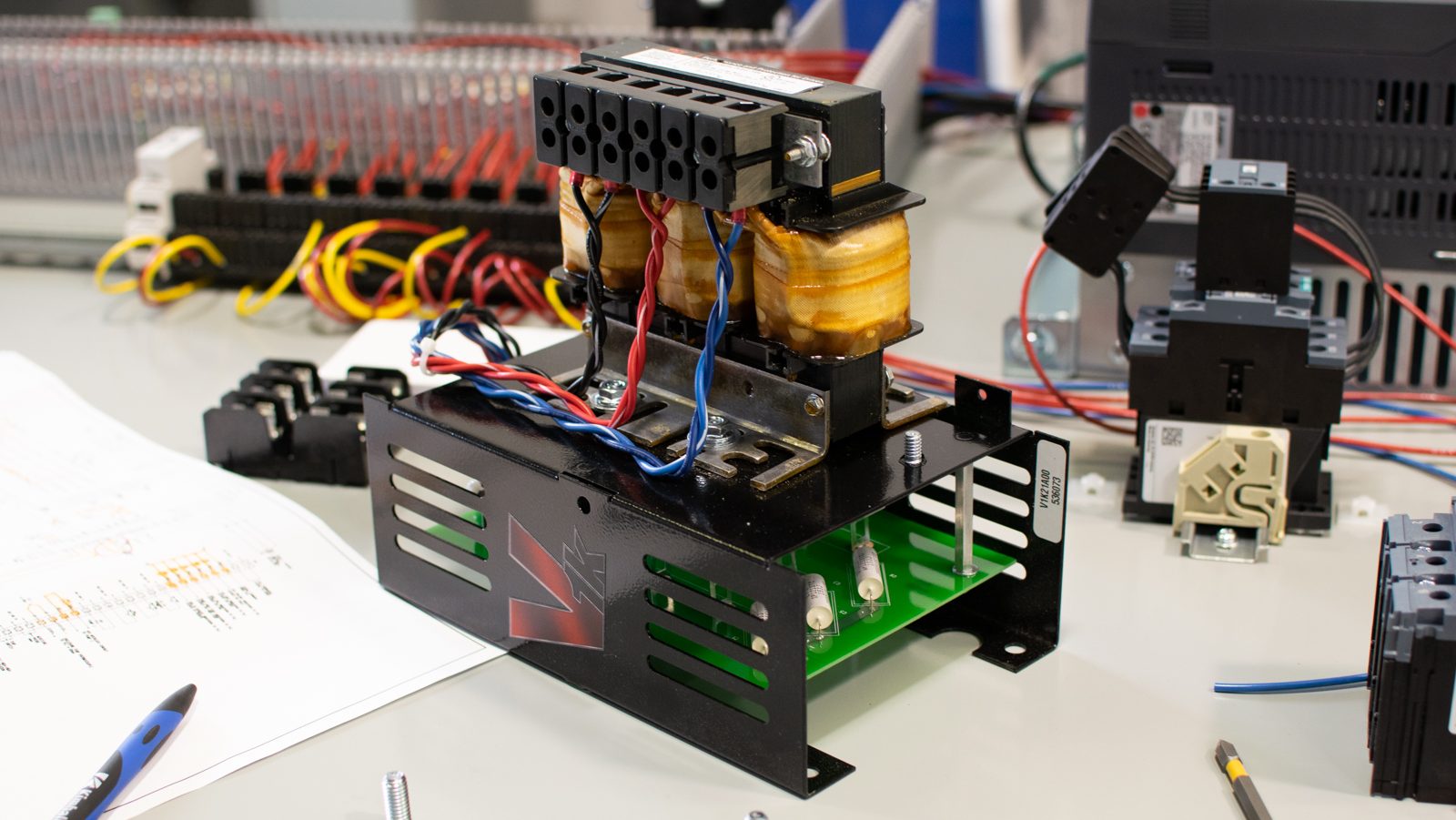

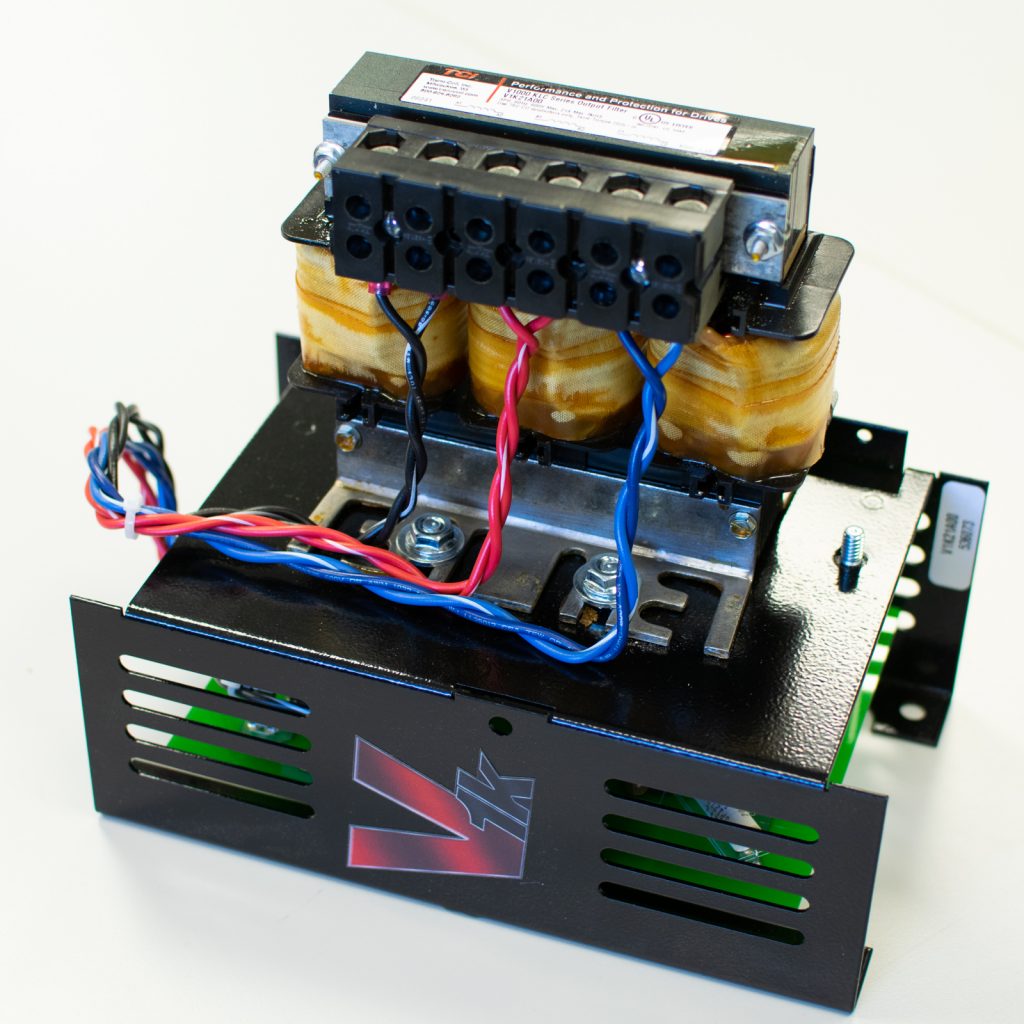

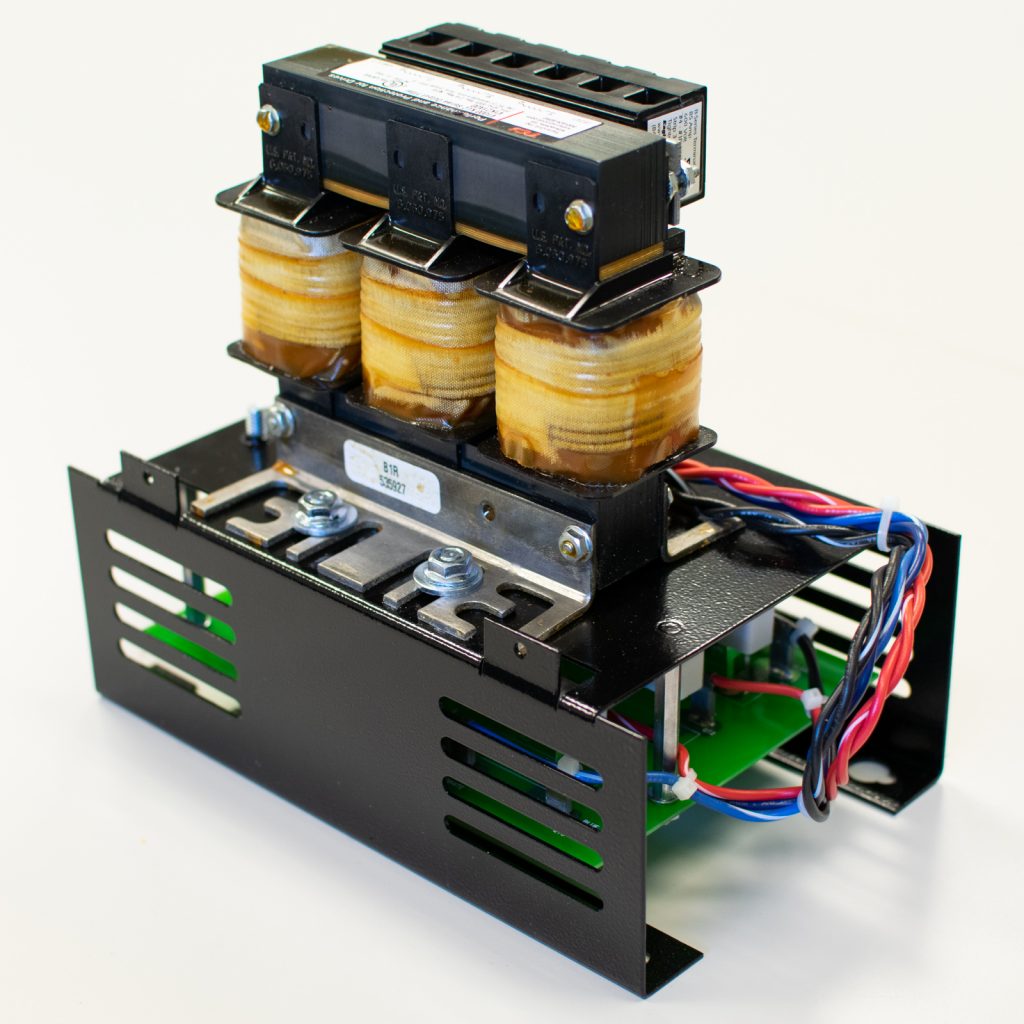

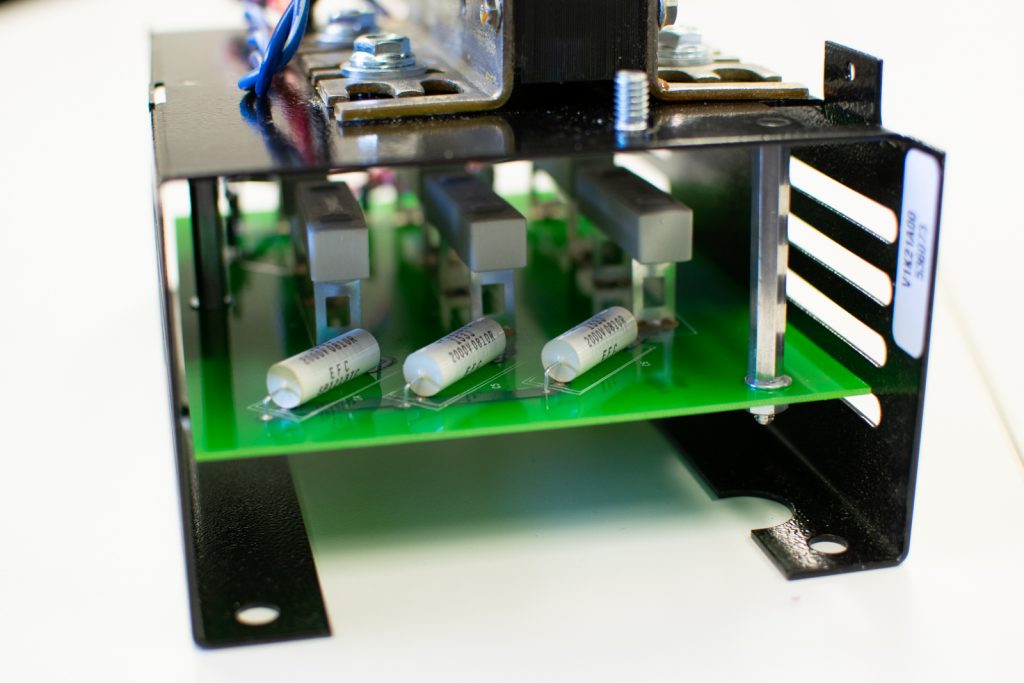

The simplest option to address dV/dt is to add a dV/dt filter. This device works to reduce the voltage spikes that amplify themselves over the distance of the lead. They tend to be the most economical options to address dV/dt, although the exact setup and performance may vary by design or manufacturer.

In situations with a much longer lead length or a higher concern about motor failure, you may need a more thorough solution. In these cases, you may want to look at a sine wave filter. This device takes the PWM waveform from the VFD and converts it back closer to the original sine wave, significantly reducing the risks of most long lead length applications. This solution is more expensive, sometimes as much as the VFD itself, but is a more effective solutions to eliminating dV/dt when better results are needed.

We Can Help!

When addressing dV/dt issues in your system, it is important to consider what your situation and needs are. How long are the lead lengths and what is the cost of motor failure? Contact us and we can help you to figure out what your system might need in order to deal with dV/dt.