Bearing Currents

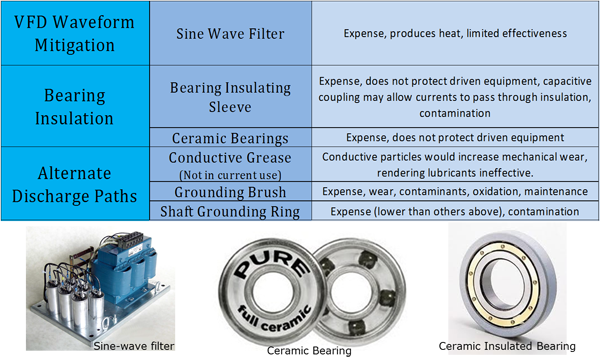

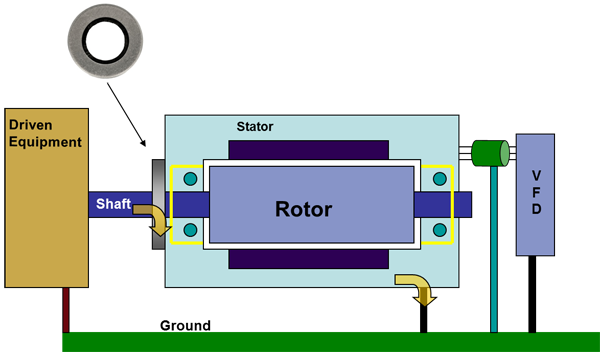

Motor bearings have a higher failure rate when the motor is run with a VFD. This is due to currents in the motor bearings. The classic solution to this problem is insulated bearings. Insulated bearings insulate the bearing using either ceramic balls or an insulating ring between the bearing and the motor frame. Another solution to this problem by the manufacturers of the Aegis bearing protection ring is shown below.

Running a motor off of a VFD shaft voltages appear:

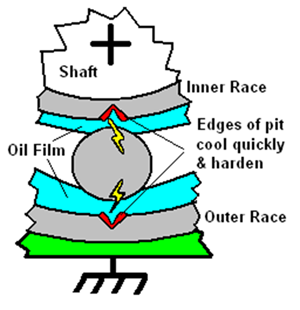

- Voltage builds up until it exceeds the insulation level of the bearing’s oil film layer – the “break-down” voltage of the bearing.

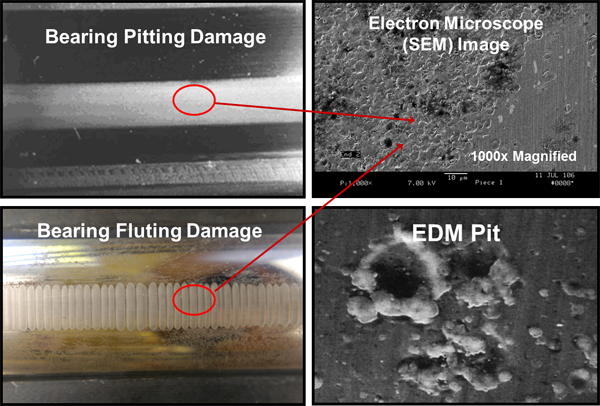

- The voltage then arcs through the bearing creating an electrical discharge machining (EDM) pit.

- Thousands of pits per second may be created and over time the ball rolling over the disturbed surface can cause “fluting damage”.

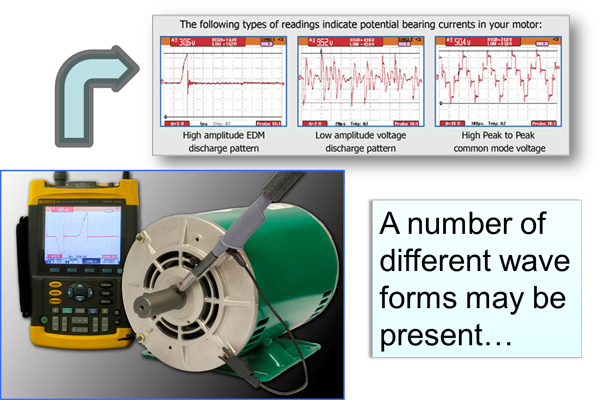

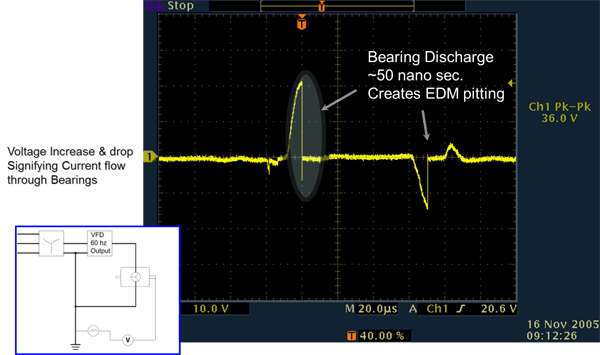

Just because there is a voltage across the bearing does not mean that there is any current in the bearing. The shape of the voltage waveform, however, can be an indication of current discharges through the bearing. Note how the voltage builds up and then suddenly goes to zero with an overshoot. This vertical line, with overshoot, is an indication of a bearing discharge. This is why it is critical to use a high frequency oscilloscope when measuring bearing voltages. A slower oscilloscope would not be able to properly show the vertical line that indicates a bearing discharge.

Advantages of Aegis Solution:

- Discharges shaft voltages to ground

- Easy to install

- Maintenance free

- Improves VFD motor bearing reliability

- Best ROI - Small investment

- Addresses the root cause of the problem (shaft currents)

- Diverts the shaft current away from the motor bearings

- Protects motor with highly reliable solution

- Longest lasting protection

- Wear rate less than 1 mill per 10,000 hours operation

- Lasts for over 200,000 hours operation

- 2 million direction reversals - Zero fiber fatigue or broken fibers

This bearing protection ring will not only protect the bearings in the motor, but also the bearings in the driven equipment if there is conductivity between the motor and the driven equipment.

The shaft protection ring may be mounted either on the drive end (back) or the opposite drive end (front) of the motor. Shop Shaft Grounding Rings