What's New in VFDs - SmartD

Variable frequency drives have been controlling motors for over forty years, but they’ve always introduced power quality issues as a side effect. Harmonics, dV/dt, and common mode are known issues to address with every VFD.

The methods of tackling these problems have varied. Some choose to ignore these issues and just hope that the collateral damage is minor. Some address it with additional filters, often built into panel systems.

SmartD has taken a different approach to handling power quality issues that is worth the time to learn about. They’ve built everything into one easy VFD chassis.

Simplifying packaging is standard in every industry, so why is this just hitting the VFD market? To understand that, you have to understand the typical layout of a VFD.

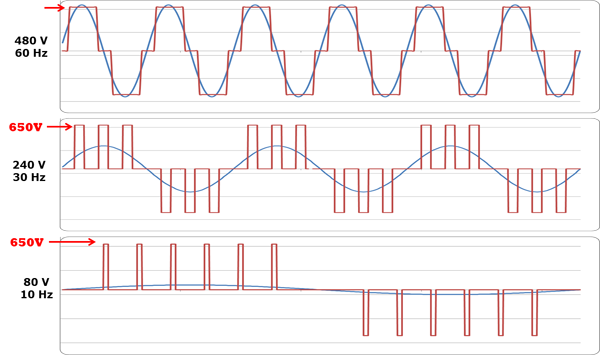

Power comes into a series of diodes on the front converter end of a VFD. On the back end, a simulated sinewave, known as Pulse Width Modulation, is generated by IGBTs, or Insulated Gate Bipolar Transistors.

Example of how a PWM waveform functions.

This topography is the reason for power quality issues related to VFDs. On the input line side of the drive, harmonics are generated by the converter. On the output load side of the drive, common mode and dV/dt are side effects of the PWM waveform.

Why are these issues, and how are they currently addressed?

Harmonics lead to a whole host of problems, the main issues being premature equipment failures and getting on the bad side of the electrical utility. This can be handled by adding additional filters like reactors or harmonic filters. Another option is an active front end (AFE) drive, which uses IGBTs on the converter section instead of diodes, cutting down on harmonics. You can learn more about harmonics issues here.

dV/dt leads to premature motor winding failures from excess heat. This is typically addressed with an output filter such as a reactor, dV/dt filter, or sinewave filter. You can learn more about dV/dt here.

Common mode leads to bearing damage as the voltage potential seeks a path to ground from the shaft of the motor. This is often reduced through some type of shaft grounding, like an SGR, or a common mode filter. You can learn more about EDM damage in our shaft ground rings article here.

If you address each of these issues, the full VFD system starts to get increasingly complex. This is where SmartD comes in.

The main advancement that makes SmartD able to simplify this entire system is Silicon Carbide, or SiC. Instead of using a traditional IGBT as a transistor, SmartD integrates SiC MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) technology as the switching device. This allows higher switching frequencies for smoother sinewave output, as well as reduced footprint. Instead of large components, you’re now able to package an active front end into the chassis of the drive to tackle harmonics. By adding these SiC MOSFETs into the drive, you have a single chassis that addresses all the major VFD issues.

SmartD VFD Chassis

Harmonic distortion? Under 5%, beating the strictest IEE519 requirements.

dV/dt? Not with a nearly perfect sinewave output.

Common Mode? Already handled within the drive.

Even other issues that you may worry about are addressed with SmartD technology. The power factor is near unity at 0.98. The drive is regenerative, able to put excess power back onto the grid instead of dissipating it through a braking resistor. It’s on the leading edge of VFD technology derating, with standard derates not starting until 50°C (122°F) and 2000 m (6600 ft) above sea level. Cable sizing can often be reduced due to cleaner power. All of this without losing efficiency, operating above 96%.

This entire system is offered in one single chassis. No additional filters, no wiring in other devices. This makes everything simpler, from specifying to ordering to installation. A simpler package is more attractive for electrical departments, maintenance teams, and even purchasers.

Is the SmartD drive right for every application? Not necessarily. There are still situations where the cost of handling the power quality issues associated with drives is not worth the technology you get. Smaller VFDs that are part of larger electrical systems may have relatively low power quality impact and might not be worth this level of advanced technology.

There are also still some limitations on the SmartD side. Their drives are available rated for 480 V and 600 V systems, but no current line for 240 V is offered. The line is also growing in amperage ratings, with the current amperage range for the company ranging from 23 to 82 amps at normal duty. SmartD says that both smaller and larger frame sizes on their way, so soon it will be available for even more applications.

Even with these limitations, the drive is a great match for many systems on the market. It’s a fantastic way to simplify installation while getting industry-leading performance.

With more electrical demands being placed on every system and a push for cleaner energy, the choice to ignore power quality issues generated by standard VFDs gets harder every day. Who knows what the future holds for our industry, but SmartD is out there pushing the boundaries of that future.