VFD Lifecycle Planning

As electrical teams try to do more with less and extend the life of equipment, they often overlook variable frequency drives. With no critical maintenance like oil changes needed, VFDs usually only get noticed when they start smoking or take a critical process down at 2 a.m.

If your team can get past the mode of fighting the maintenance fires as they pop up, you can start to engage in a process called “lifecycle planning.” This process helps you to extend the life of your equipment and be prepared to replace equipment as it’s needed, avoiding future emergencies.

In this article, we’ll cover what lifecycle planning is, making it more than a corporate buzzword. We’ll look at how you determine your status and what you should inspect. Then we’ll cover the research and planning you need to do to extend the life of VFDs and know what future problems and costs you can avoid.

What is Lifecycle Planning

Many maintenance teams have seen corporate initiatives come and go, and at first look it could seem like lifecycle planning is a similar concept. Unlike corporate fads, lifecycle analysis and planning is a solid process that helps to avoid future emergencies. When done properly, it makes sure you have complete information about:

- What equipment you own

- The condition of the equipment

- What equipment and failures are repairable

- What replacements are available and what is obsolete

- The cost and timeline for all these details

When an emergency pops up, these are all details you need. Picture a standard emergency failure that we’ve seen happen hundreds of times.

You’re at home and you get a call. A VFD failed. What are the questions you ask?

- Which VFD?

- How did it fail?

- Can we repair it?

- Do we have a spare?

- How quick can we get a new one?

- How much is all this going to cost?

The idea of lifecycle planning is to get this information ahead of time to be able to avoid those emergency calls, and when the emergencies happen you already have that information ready to go.

The steps to lifecycle planning are simple, but that doesn’t mean they’re easy. A large part of it involves intimate knowledge of the products and their potential failure points. Most often we work directly with facilities to help conduct a lifecycle analysis.

Some facilities have the experience needed in-house. Others want to get as far as possible without bringing in contractors. To help with that, we’ll go through the things you should consider during this process, and it all starts with figuring out where you currently are.

Identifying Your Current Status

The first step in identifying your current status is to identify the assets you have. Often, we’re given an asset list with model or serial numbers, sometimes with a local identifier like “Pump # 12.” While this is helpful, it’s only the surface of what you need.

Facility and Asset Documentation

When you compile a list of assets, start by documenting everything implemented in your system. If you’re doing this process for VFDs, you likely also want to document where that power is fed from and the motor it controls.

In addition to the identifying information on the drive, identify how it’s been run and what may affect its lifespan. Note asset age, installation date, runtime, process, criticality, environment, access requirements, and relevant team members or management.

Example Assist List:

| Plant 1 - Pump 12 VFD | Plant 1 - Pump 13 VFD | Plant 1 - Fan 7 VFD | Plant 1 - Fan 8 VFD | |

| Model # | Galt G540-01800UL-03 |

Mitsubishi F840-02600-E3U6 |

LS LSLV055G100-4EOFN |

Invertek ODE-3-420300-3F4A |

| Serial # | 123456 | 654321 | 987654 | 456789 |

| Install / Age | 05/12/2021 | 05/12/2021 | 08/07/2023 | 02/05/2019 |

| Runtime | 6200 Hours (as of 12/10/25) |

15400 Hours (as of 12/10/25) |

4500 Hours (as of 12/10/25) |

17100 Hours (as of 12/10/25) |

| Process | Fresh water centrifugal pump | *Critical* Fresh water centrifugal pump | Exhaust fan | Exhaust fan |

| Environment | Clean, risk of splashing, temp controlled |

Clean, risk of splashing, temp controlled |

Clean, dry, 0°-50°C | Clean, dry, 0°-50°C |

| Team | Managed by Plant 1 I&E | Managed by Plant 1 I&E | Managed by Plant 1 I&E | Managed by Plant 1 I&E |

Looking at the example list above, you can see the help that a true asset list like this can provide. If you were to look at the two pumps on the list, they were installed on the same day but are different sizes, and one of them has over twice as much runtime as the other. If the Plant 1 / Pump 13 VFD were to go down, you’re dealing with a much more critical and highly used piece of equipment than Pump 12’s VFD, as well as an environment with splashing. It’s only a few years old which raises questions about why it failed prematurely. If you have additional questions, you know who to reach out to: the Plant 1 I&E team.

Without looking up a single spare part or replacement, you already are better prepared to address the emergency. You may not yet have a list of possible replacements or spares, but you know the manufacturer, the sizing, and can make educated guesses about whether this is old enough to be obsolete yet.

It's important to note that you should also be documenting critical spares and replacement parts. If you stock full VFD panels, VFD chassis, or spare capacitors and boards, document those as well. This creates a list with a full view of the assets at your disposal to solve the issue.

Condition Inspection and Determination

Once you have a complete list of your equipment, the next step is to inspect that equipment and determine its current health status. You’re looking to know whether you have anticipated problems, such as the beginning stages of a failure you should prepare for.

These inspections may seem simple but should be conducted by trained and certified individuals just like any other electrical work. The risk of arc flash and other problems is always present, so training on proper LOTO and other safety processes is vital.

The first step is visual inspection. Note the environment, how clean the panel, VFD, and components are. Look for any burned wires, damaged components, or anything else that obviously looks out of place. Because of the range of issues here, this is one of the hardest parts of the entire process to have a comprehensive checklist. Much of the inspection is knowing what looks normal from experience and looking for anything outside of that range. As part of the visual inspection, look at connections and terminations, checking that they are properly torqued and there’s no signs of looseness, contamination, or burning.

One of the weakest points in VFD buildups tends to be capacitors. Because of this, those are some of the most important parts of the system to test. DC bus ripple testing helps to determine the health of DC bus capacitors. These capacitors smooth out the voltage, so low ripple means the capacitors are doing their job. The higher the ripple, the more likely that capacitors are failing. You’ll often see this start to increase as capacitors begin to age, which helps you to determine that replacement parts may need to be sourced. This test can be performed with an oscilloscope, RMS meter with ripple capability, and occasionally by a drive’s own diagnostics if it has a “DC Ripple” or “Bus Health” parameter.

Some capacitors in VFD systems are not part of the DC bus. Passive harmonic filters have capacitors on the input side of the VFD. You can test these capacitors as well. Note that these are AC capacitors and not DC like internal VFD capacitors. Test the phase-to-phase current imbalance with a meter.

Fans are another crucial component to test, especially with how important it is to keep a drive within its rated temperature range. Check for function and airflow, also checking air filters. It’s helpful if the team signs initials and dates right on the filter when changing them so it can quickly be identified how old a filter is. Even then, the useful life of a filter varies by the cleanliness of the environment, so look for signs that it’s dirty or impeding airflow.

Look through the fault logs on the drive. Warnings that occur once every few months should be viewed differently than major errors that occur multiple times a day. The fault log isn’t perfect for diagnosing VFD health as it may show issues with the VFD, but it may also show issues with the motor, driven equipment, or incoming power.

One step that’s often overlooked is a discussion with the team who works with the equipment. Whether it’s maintenance, electrical, facilities, reliability, or I&E, that team likely has anecdotal knowledge of the equipment and how it behaves, as well as issues they’ve seen. Faults may not show because the team knows the individual quirks and is accommodating them. They may know about small failures that don’t get sent up the chain, such as replacing capacitors every few months instead of years. This is also where you may learn how parameters have been changed for the drive to make it run in a certain way that may not be optimal for the process. These types of insights help give a full picture of the equipment.

These conditions and findings should be documented with the asset list. Depending on the system you have, this may be a digital or physical system but make sure it’s easily accessible to anyone handling an emergency as well as those doing future planning.

Planning for Next Steps

The easiest way to make decisions in an emergency is to have the path mapped out before. This is where planning turns to action. Now that you have an asset list with inspection reports, you can get technical experts and other decision makers in a room to determine next steps when they’re needed. The answers to some of these questions may take some research.

Planning for Maintenance

Plan for the maintenance that’s needed. Determine the spare and consumable parts needed, where to get them, and the appropriate amount to keep on hand. Consumable parts will often include things like air filters, while spares will include common failure points or critical pieces. Capacitors are often a smart thing to keep on hand, while more technical facilities may want to keep boards and other parts on hand.

It is also worth noting that you don’t have to keep these on your own shelves if you have a partner who has them readily available. We often act as the stocking partner for many facilities, keeping filters, capacitors, boards, keypads, and other components stocked and local to their plant. Developing that partnership builds trust that whenever there’s needed maintenance, someone has those parts ready to go. Arrangements such as purchasing the products and storing them at a vendor, vendor managed inventory (VMI), or other processes can be common ways to achieve this.

Planning for Repair or Replacement

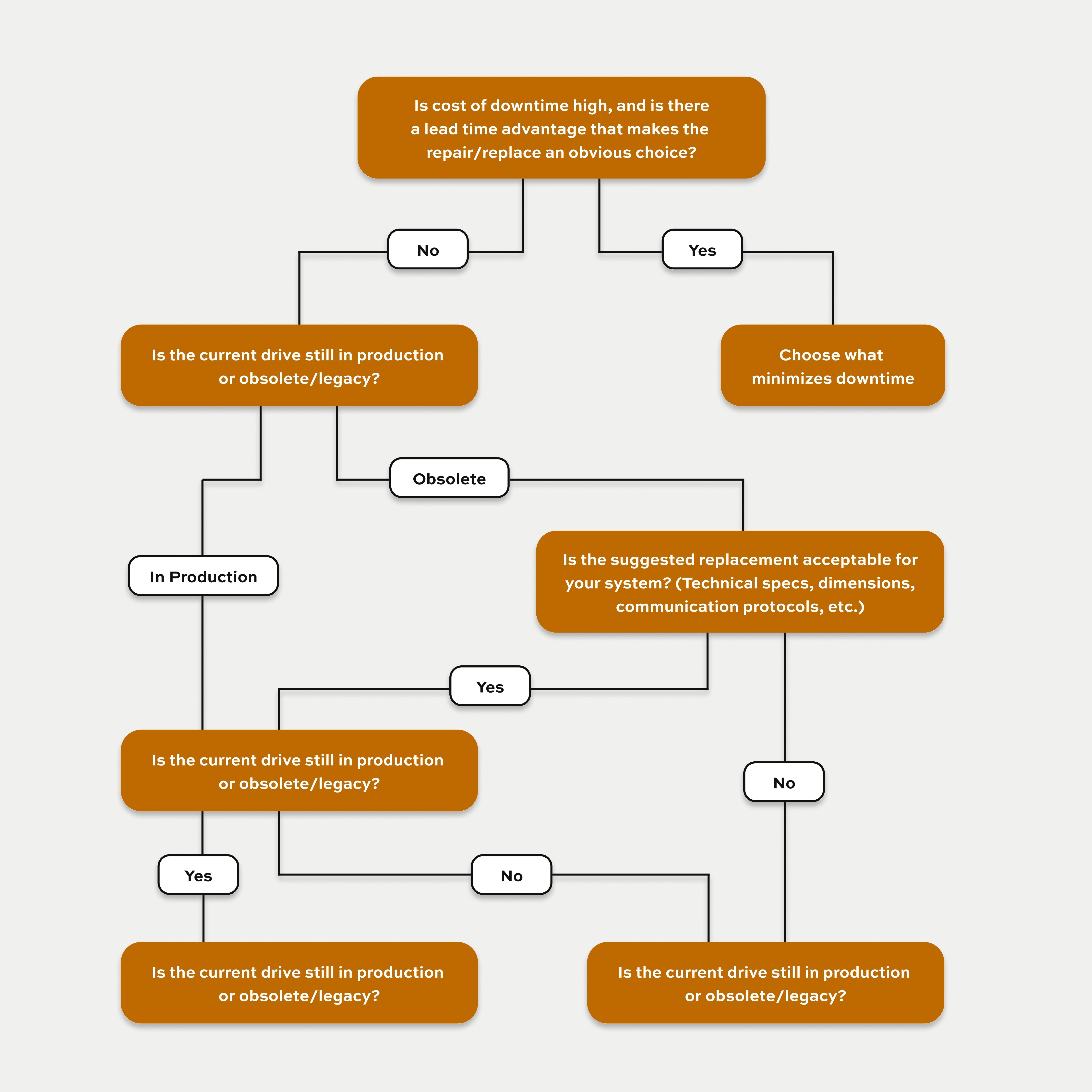

When something fails, determining whether you should repair or replace may seem tough. If you have already done an analysis, you likely have answers to the questions in the following decision tree and can make quicker choices.

Improving the Sytem

Although no one wants a failure, it can be a great opportunity to make your future system even better. When a repair or retrofit replacement has to happen, you get the chance to do other work and minimize downtime, labor costs, and potentially even supply costs. Preparing for these ahead of time also makes it much smoother.

When you look at each system, evaluate factors like harmonic mitigation, power factor correction, future communication or building management system (BMS) upgrades, or enclosure improvements. If these are in the future for your systems, have the parts or the plan ready, then when you perform either maintenance, repairs, or replacement you can quickly upgrade your VFD system.

How long does a VFD typically last?

VFD lifespans vary based on many factors, including usage, environment, and topology. In general, a low voltage VFD will last about 10 to 15 years, although it can be much shorter (or longer) than that. Medium voltage VFDs often last longer, with an estimated lifespan of 15 to 20 years.

Let us Help

Many parts of lifecycle analysis and planning can be done by your team, and they should always be involved because of their knowledge and expertise. We still find that many are unfamiliar with the intricacies of VFD systems and need help going through this process but find value once they do it. Reach out to our experts to ask about how we can help you with your lifecycle planning process at 1-800-800-2261.