7 Questions to Ask When Buying a VFD Control Panel

Do you know how to find a quality enclosed VFD control panel?

Here are 7 questions you need to ask yourself (and your supplier) before buying a VFD control panel:

1. Do you have the right VFD for the job?

When sizing a VFD to run a motor you must consider: The application, the motor name plate data, how it is being controlled and the environment in which it will be operating.

- Application

- A VFD needs to be capable of handling the overload of specific applications. Industry standards are 110% overload (typically fans and pumps) and 150% overload (typically loads that are “hard to start” or that surge like conveyors, mills, many compressor types, and more).

- There are several reasons to make sure that you have the correct overload rating on your VFD. Sizing the overload rating too small could potentially prevent your application from running at all, while sizing it too big might produce added costs and perhaps even end up damaging the motor. When examining the application, other issues such as regeneration (common on elevators and downhill conveyors) may become apparent and may require additional equipment in order to operate properly.

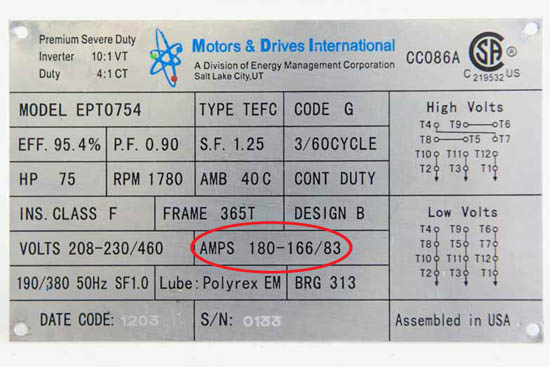

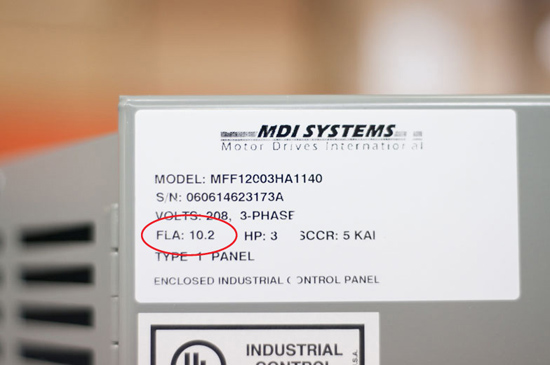

- Motor Nameplate Data

- When sizing a VFD you must take into account the motor it will be running. Almost all the information you need can be found right on the motor name plate. HP, Full Load Amp rating, voltage, and number of phases of the motor. Matching these four pieces of data to the VFD is critical to ensure proper functionality.

- When sizing the VFD, you must compare the System Amp Rating and the motor amp rating (see pictures below). The system must have a higher amp rating than the motor, and sometimes much higher if you are de-rating the VFD for a specific application.

- Controlling your VFD

- Most VFDs can either be controlled from a keypad is provided with the unit and/or through a computer system (SCADA networks, Profibus, DeviceNet, etc.). When controlling a VFD from a computer system, it is important to know what protocol you are planning to talk to the computer with. You may have to purchase an additional option card to allow the VFD and your computer system to communicate.

- Environment and Location

- Where you mount the VFD control panel will determine what type of enclosure you need (NEMA 1, NEMA 3R, NEMA 4X, etc.)

- The altitude and ambient temperature are two important factors in deciding how much cooling is needed to keep the drive operating properly.

2. Is it easy and safe to maintain your panel?

It is very important to consider how safe and easy it is to maintain the panel you are about to purchase. Maintaining a panel will help to ensure the longevity of its life which all comes down to saving you money. Below are some areas to consider when making this decision:

- Filters

- Opening the cabinet door to change the filter can pose an unnecessary arc flash hazard. Making sure your filters are easy to change is an important safety element you need to consider.

(Shown: An interchangeable filter outside of the cabinet door)

- Pad lockable circuit breaker disconnect

- A circuit breaker disconnect shuts off the power before you open the cabinet door. This is an important safety feature that can prevent injuries and deaths, especially for larger systems.

- A pad lockable door handle can keep unauthorized intruders from entering the cabinet, or powering on/off of the system. This not only provides security but also adds a layer of safety. In many areas it is required by code. However, it’s always good practice for safety even without the requirement.

(Shown: a pad lockable circuit breaker disconnect)

- Permanent wire marking

- Have you ever tried to trace a wire that has no marking? Permanent wire marking is a great time-saver when the system requires maintenance, troubleshooting, as well as during installation.

- Job specific drawings

- Are the drawings specific to your VFD panel?

- Manual

- Does the panel come with an OEM operator’s manual?

3. Are you keeping your VFD cool, clean and dry?

Keeping your VFD cool, clean and dry is essential to the longevity of its life. You can attain these 3 elements by checking your setup:

- Filters

- Again, is it easy to change?

- Cooling

- There are many different ways to keep a VFD cool. Our preferred method is using fans to keep the enclosure positive-pressure ventilated. You can also consider options like air conditioning or cold plate technology.

- It is important to consider the ambient temperature surrounding the VFD and then decide the best way to cool your VFD inside the panel.

- Redundancy

- Do you have a backup plan for your cooling method in case of component failure? The picture below shows 2 smaller fans installed instead of 1 big fan, in case one of the fans fails.

4. How are you controlling and monitoring your VFD panel?

- HMI (Human Machine Interface)

- A good option of HMI is a graphical numeric keypad or a touch screen tablet (shown below). They will save you valuable time when programming and troubleshooting.

(Shown: Mitsubishi Keypad FRPU0701)

- Signal Lights

- LED pilot lights installed on the front of the panel will give you real-time updates of the status of your control panel.

- All-in-one enclosure

- Is everything included inside one UL listed enclosure, or are there components in separate enclosures that require extra wiring? Or does it come in pieces that require assembling? In most cases, it is the most convenient to have an all-in-one enclosure.

5. What should you know about certifications and warranty?

- UL Listing

- A UL listing certification is often required to meet the NEC code. Check and make sure that the panel shop you use to build panels is a full UL panel shop, and confirm your panel is a UL certified.

- Warranty

- Does the manufacturer stand by their products? A standard warranty of a motor control panel is at least 1 year.

(Shown: a UL certified panel should have a UL sticker with serial number on the front)

6. How is your power quality?

Power quality is often regulated by the utility company.

- Line & DC bus reactors

- Is the drive protected from power line surges? A line reactor should be the minimum protection for VFDs from surges and harmonics.

- Harmonic filters

- Do you need to meet IEEE519 or utility power quality standards? If so, you may need more than a line reactor or DC link choke. In that case, harmonic filters are an economical solution.

7. Do you need any optional equipment?

There are a lot of optional pieces of equipment that can be added to your panel. Many of these pieces of equipment are beneficial but may or may not be needed. Below are some optional items with descriptions as to when there might be a need for it.

- dV/dt filter

- If the motor is more than 500 feet from the panel, you might need a dV/dt filter to prevent insulation failure of the motor.

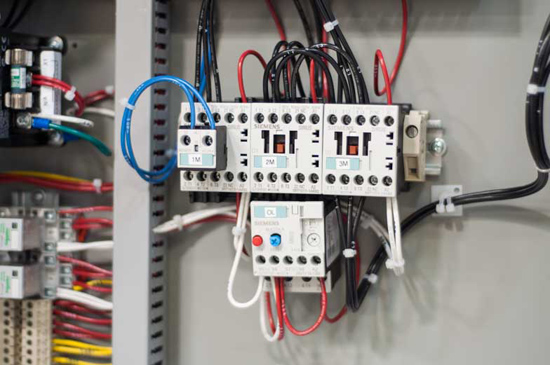

- 3 contactor bypass with CPT (control power transformer):

- Is the bypass completely isolated from a VFD failure? Is there a separate oil-tight bypass switch on the enclosure? Our engineers choose 3 contactor bypass over other options because it isolates the VFD from the system for repairing without shutting off the system. It is simple, inexpensive, and easy to control.

- Other specific accessories for your applications:

- PLC

- A redundant VFD

- Soft starter

- Modem

- Phone dialer

Although these 7 questions will help you in purchasing the right VFD control panel, clearly there are a lot of items to consider when purchasing a VFD. The best way to ensure that you are getting exactly what you need is to work with a manufacturer who is knowledgeable so that they are able to recognize your specific needs.

For information about custom VFD control panels, take a look at www.vfds.com/custom-vfd-panels.

To see our full list of VFD control panel and soft starter panel inventory, take a look at www.vfds.com/electrical-control-panels or check out these 3 series of VFD panels designed for various purposes below.